PRESENTATION

Our Business Developer presents Thermocoax Aeronautic

How is Thermocoax involved in the Aeronautic market? What are the advantages of working with Thermocoax? Take a listen or read the responses of Olivier Herve, our Business Developer.

THERMOCOAX is a leader in the manufacture of mineral-insulated cables and in the development of thermal solutions for the aeronautic's industry.

PRODUCTS

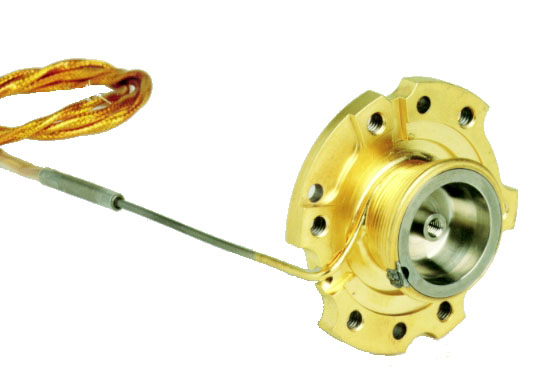

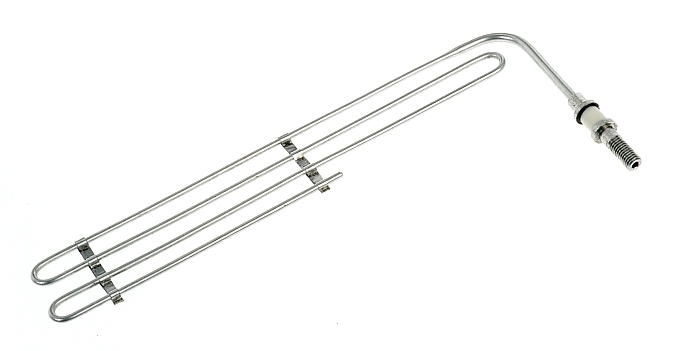

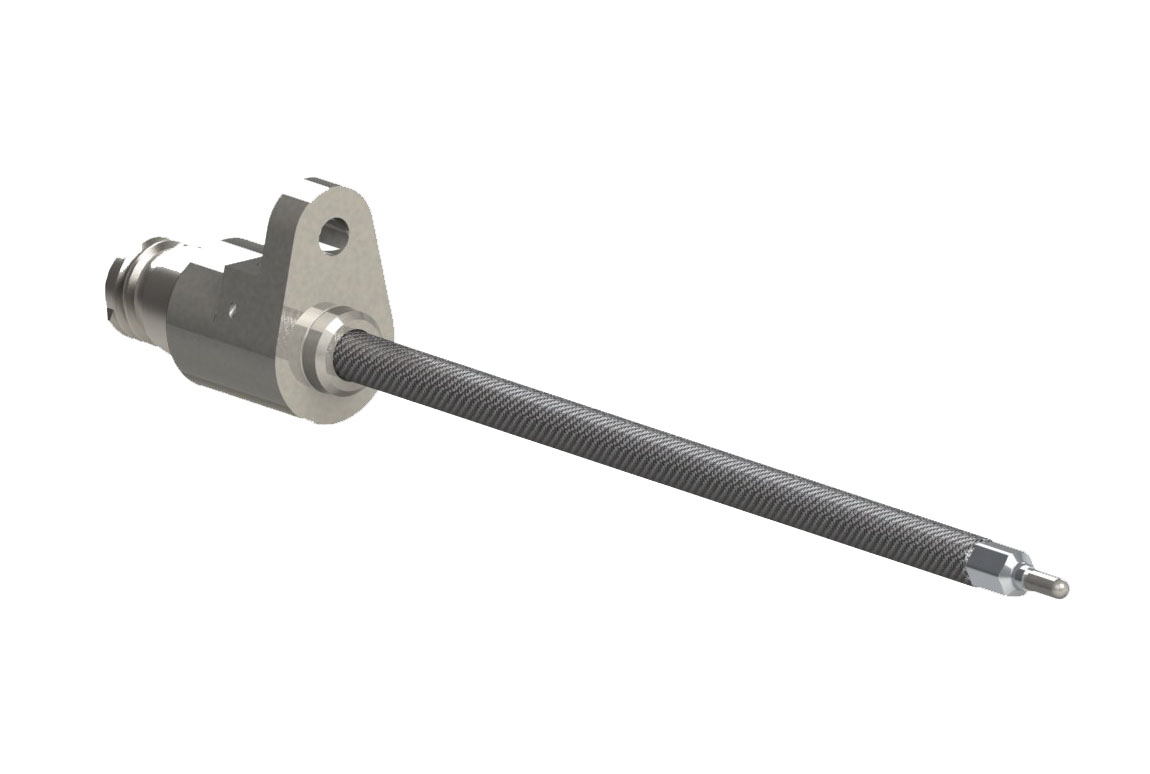

Thermocoax offers in the Aeronautic & Defense markets heating systems for anti-icing (pitot tube, AoA, TAT, waste water drain mast) but also temperature sensors for gas engines, braking systems and bleed air leakage detection.

In Defense, we are a key supplier with debris monitoring sensors for jet propulsion. We develop and manufacture specific heating system Male drone’s camera and combat drone.

CORPORATE NEWS

- Thermocoax’s individual commitments to act4nature international

- Biodiversity at Thermocoax through insect hotels

- Moves of our factories in Normandy towards our new building in Caligny !

- Thermocoax applications set on satellites dedicated for space debris clean up !

- THERMOCOAX on board Soyuz-2 number 90, launching happened 22nd March 2021.

- Gender equality index in 2020

- Carbon neutral by 2040

- THERMOCOAX, part of the new space propulsion technology of the key occidental Geosatellite makers.

- H2O2 sterilization units for Filling machines

- Fusion reactors : THERMOCOAX cabling solutions in the heart of ITER reactor