Heating Tools for Shaping and Heating Mold

Heating Tools for Shaping and Heating Mold

The new generation of composites requires high curing and shaping temperatures, above 400°C. The aerospace industry is looking for heating tools to deploy their for Out of Autoclave Process policy. The maintenance industry is developping repair kits and methodology for heating tool solutions.

The new generation of composites requires high curing and shaping temperatures, above 400°C. The aerospace industry is looking for heating tools to deploy their for Out of Autoclave Process policy. The maintenance industry is developping repair kits and methodology for heating tool solutions.

Thermocoax, based on their insulated cable produced in house and experience in heating tools in general and automotive industries, provides heating tool technology for shaping PEEK parts, heating composite molds, PEEK repair.

Heating Tool Applications Description:

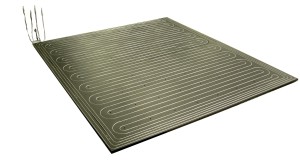

Out of Autoclave Process: Heating Tools by contact

- Heating mold up to 450°C.

- Best homogeneity +/- 2°C

- Fit complex/3D shape

- True cold hands, no limitation for bending position

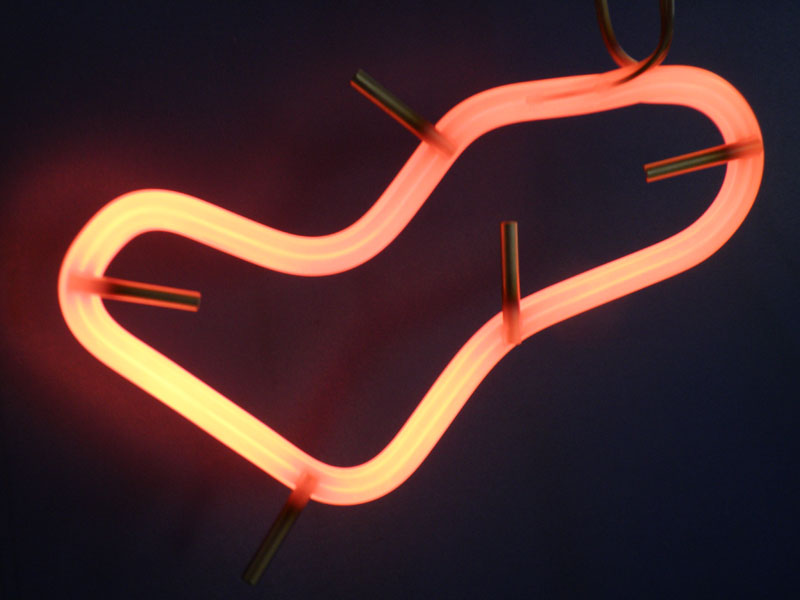

- Shaping and Joining: No contact heating tools

- Fixed on a specially-designed support, the heating tool cable reach the infrared range.

This technology offers various possibilities for shaping. Heating tools generate temperatures up to 450°C for thermoplastics, suchas PEEK parts for instance. Based on automotive experience, we can use heating tools to join and weld two PEEK parts together without having contact with the heating tools.

THERMOCOAX’s heating tools give the advantage of:

- Fastest operation for higher productivity

- No dust to save cleaning operation

- No burring

Heating Tools Key Parameters:

- Up to 1000°C

- True colds hands, single or dual cores

For instance 100 kWatt under 400 volts with 4 loops of heaters

Cable diameter down to 1mm for high homogeneity

Cable diameter solution up to 5mm for high power

Bending radius 3 times the diameter. Rapid temperature increase